Production Manufacturing

Scalable production solutions with advanced automation and quality control

High-Volume Production

We utilize the latest equipment to scale up to your lot size requirements. Through the use of efficiency and automatic loaders, we can accommodate your production.

Our production capabilities range from small batch runs to high-volume manufacturing. With automated loading systems, robotic assistance, and advanced quality control, we deliver consistent results at competitive prices while maintaining the highest quality standards.

Request Production Quote

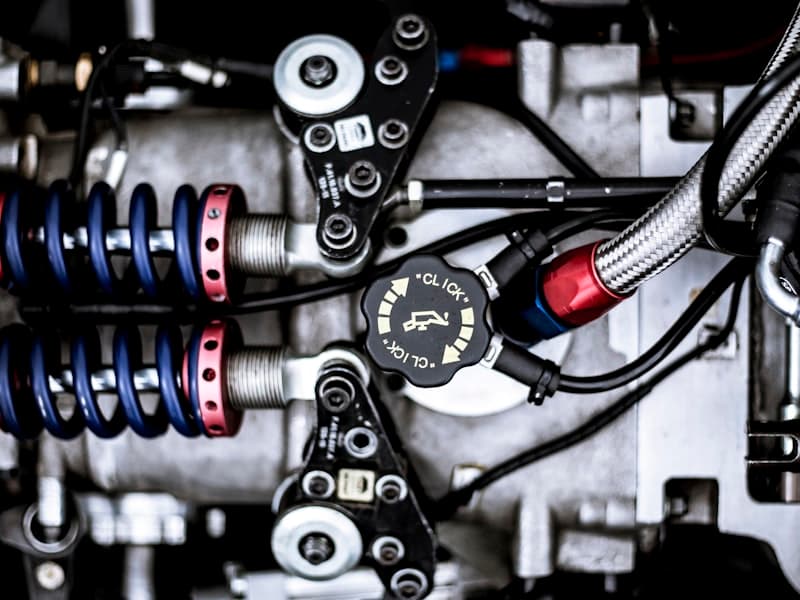

Advanced Production Equipment

State-of-the-art machinery designed for efficiency, precision, and reliability

Horizontal Machining Centers

6-pallet pool system for continuous production

- • Okuma MB4000H

- • Automatic pallet changer

- • 24/7 unmanned operation capable

Robotic Automation

Automated loading and unloading systems

- • Kawasaki RS20 robots

- • Universal Robot UR5

- • Automated part handling

Multi-Tasking Machines

Complete parts in single setups

- • Okuma LB3000 lathe/mill

- • Dual spindle capability

- • Reduced cycle times

Production Capabilities

High Volume

1 to 100,000+ pieces

24/7 Operation

Unmanned production capability

Quality Control

SPC and automated inspection

Supply Chain

Material management and logistics

Advanced Programming & Control

We pride ourselves on our efficient procedures and solutions. Therefore we utilize the latest software to program our advanced machinery quickly and accurately.

Efficient Programming

Advanced CAM software ensures optimal toolpaths, reduced cycle times, and consistent quality across all production runs. Our programming team optimizes every operation for maximum efficiency.

- • Automated programming features

- • Toolpath optimization

- • Simulation and verification

- • Post-processor customization

Quality Inspection

Satisfying customers is our top priority. That's why we believe in investing in quality inspection equipment to verify all critical measurements.

- • Climate-controlled inspection room

- • Coordinate measuring machines (CMM)

- • Statistical process control (SPC)

- • First article inspection reports

- • In-process quality monitoring

Ready to scale your production?

Let us help you meet your production goals with our advanced manufacturing capabilities and quality assurance.